Solutions for machinery and instruments for safety glass production and quality control.

PVB Treatment

PVB Shaping and Stretching

prepares PVB interlayer sheets for the production of windscreens. It gives both commercial and economical benefits to the windscreen producer.

PVB Cutting

The FCM machine cuts automatically the PVB interlayer to the desired

angle and length for windscreen production.

PVB Shaping and stretching

PVB Shaping or stretching prepares PVB interlayer sheets for the production of windscreens.

It gives both commercial and economic benefits to the windscreen producer:

- increases the aesthetic and comfort values of top-shaded windscreens.

- gives savings of 15-25 % with top-shaded PVB and 10 % with uniformly coloured PVB and wedge PVB.

Glass Quality Control

Our product line includes all normative and non-normative quality control instruments for flat glass, both for automotive or arcitectural glass, wether annealed, heat-treated, laminated or coated glass.

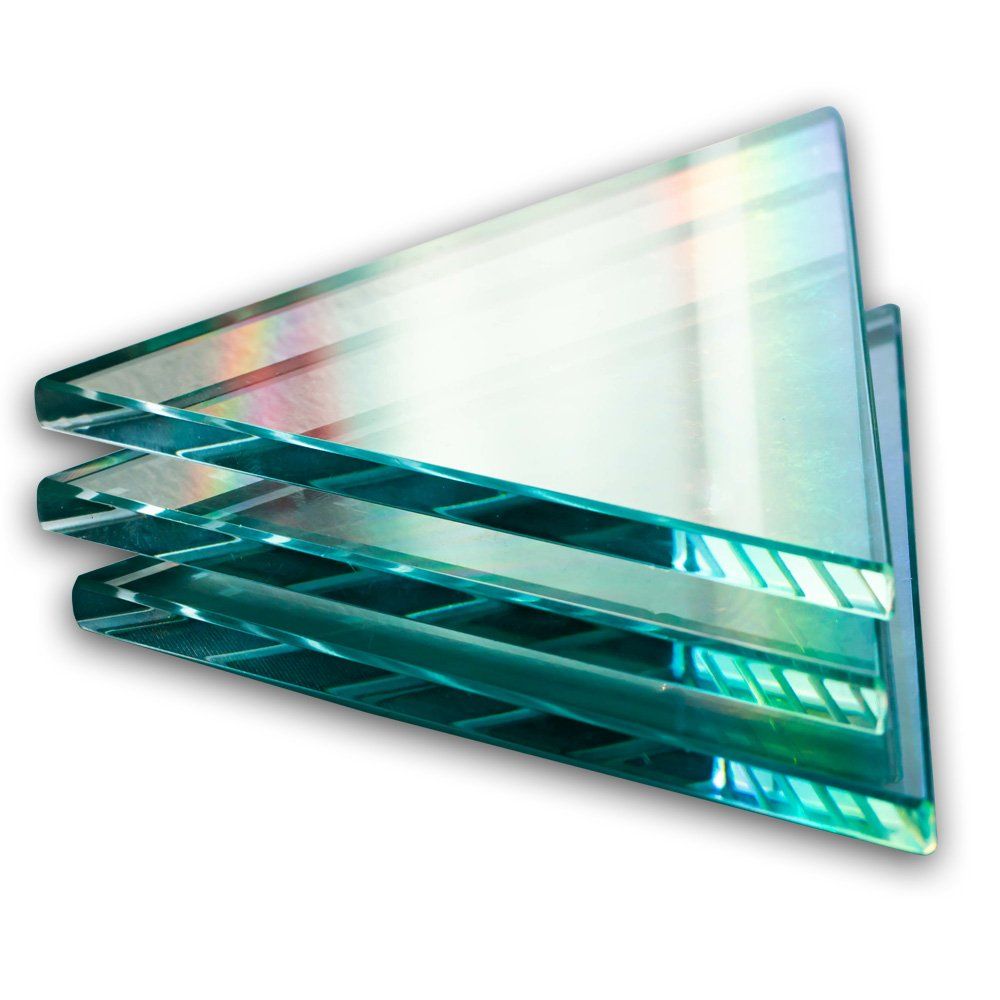

Laminated glass

Laminated glass is tested for resistance to high temperature and humidity, interlayer adhesion (pummel), ...

Other

Marine glazing, Elevator glazing, ... different applications have their own testing instruments

Automotive glass homologations

ECE R43 and DOT approvals

Complete testing service and official test reports, applications to the granting authority and delivery of the approvals, application and «agent for service» for DOT-number.

Heatable backlites

The manual soldering machine is an economic solution to solder the connectors on heatable backlites. It is well adapted for flexible production as well as for using as a back-up unit for automated soldering systems. It gives excellent results and reliable soldering quality.